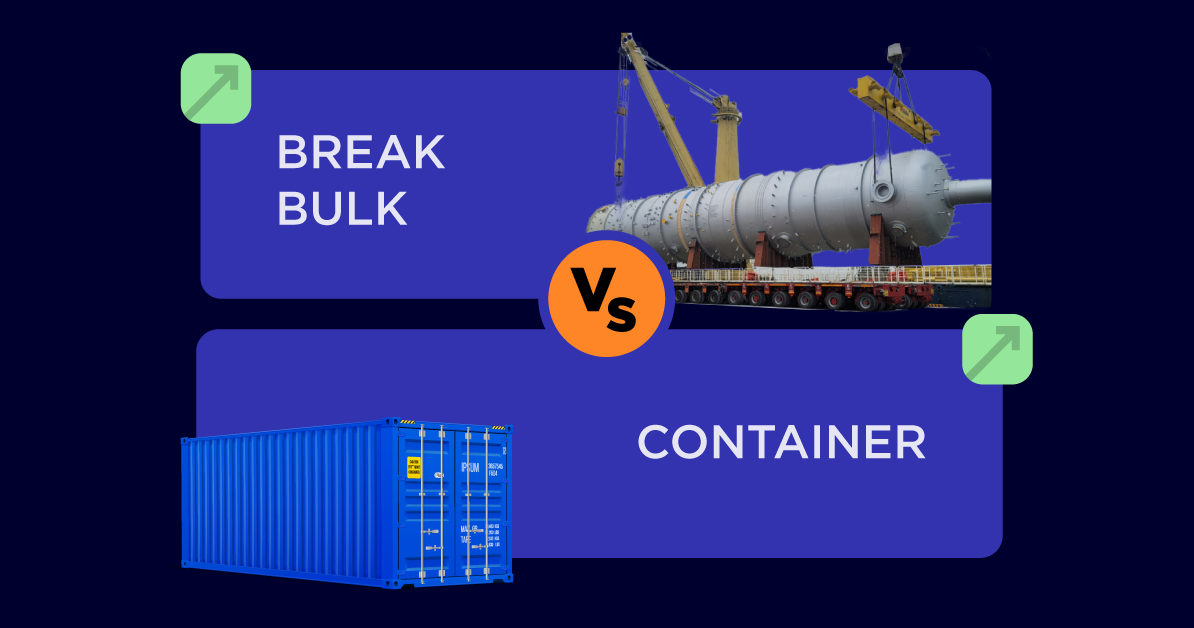

Just like people, not all cargo is built the same. Some shipments fit neatly into a standard container, while others are oversized, irregular, and need extra care and planning.

We’re talking about project cargo, industrial machinery, heavy equipment, and other massive goods that often require break bulk shipping.

Knowing the difference between container shipping and break bulk isn’t just helpful—it’s essential for cutting costs, avoiding delays, and keeping your shipments safe.

In this guide, we’ll clear the confusion and compare break bulk vs. container shipping, so you know when to go standard and when to go oversized.

What Is Container Shipping?

Container shipping is the go-to method for most cargo—especially items with a regular shape that fit comfortably inside a 20ft, 40ft, or high-cube container.

The beauty of container shipping lies in its efficiency and security. Cargo is packed, sealed, and moved as a single unit, making loading, unloading, and tracking much easier. Plus, it’s widely available, giving you more options for ports, schedules, and routes.

Most freight forwarding companies handle container shipping routinely, but the same isn’t true for irregularly shaped or oversized shipments.

When your cargo is too big, too heavy, or oddly shaped, it needs special handling, planning, and an experienced freight forwarder. That’s exactly when break bulk shipping becomes the smarter, safer choice.

What is break bulk shipping ?

Break bulk shipping is basically the solution for cargo that won’t fit in standard containers. Instead of being packed into boxes, crates, or pallets, each item is handled individually—usually with cranes, forklifts, or other specialized equipment.

We’ve covered this in detail in our guide, “What Is Break Bulk Shipping? Here’s How to Master It” so if you want the full breakdown, including loading, unloading, documentation, and tips for project cargo, check it out.

Common Break Bulk Shipments

Break bulk shipping is ideal for items that don’t fit standard containers or are oversized, heavy, or irregularly shaped. Here are some examples:

- Industrial Machinery – Large machines for factories, construction sites, or production plants.

- Wind Turbine Blades & Renewable Energy Equipment – Long, oversized blades and components that can’t be containerized.

- Steel Beams, Pipes, and Coils – Heavy, long, or awkwardly shaped metals used in construction and manufacturing.

- Construction Materials – Prefabricated structures, concrete slabs, and large building components.

- Vehicles and Heavy Equipment – Trucks, buses, bulldozers, excavators, and other oversized machinery.

- Project Cargo – Complex shipments for infrastructure, industrial projects, or energy installations.

- Large Tanks and Containers – Storage tanks, chemical containers, or industrial vessels.

- Oversized Consumer Goods – Boats, yachts, or other bulky recreational equipment.

Tip: Any cargo that is too heavy, too long, or too awkward to fit into a standard container is a candidate for break bulk shipping. Proper planning, loading and unloading, and experienced freight forwarders are key to handling these safely.

But knowing the difference between Break Bulk and Container Shipping is necessary

Break Bulk vs. Container Shipping – Key Differences

So, how do you know when to go with container shipping and when to choose break bulk? Here’s a quick breakdown:

Bottom line

Both container and break bulk shipping have clear advantages. Container shipping is efficient, predictable, and cost-effective for standard cargo, while break bulk shipping is flexible, precise, and capable of handling oversized or project shipments.

The key is knowing your cargo, planning ahead, and working with a freight forwarder experienced in both methods.

With the right guidance, what seems complicated becomes smooth, safe, and cost-effective.

Frequently Asked Questions

1. What’s the main difference between container shipping and break bulk shipping?

Container shipping involves transporting goods inside standardized containers (usually 20ft or 40ft), while break bulk shipping handles oversized or irregular cargo that can’t fit into containers. Each item in break bulk is loaded and unloaded individually using specialized equipment.

2. When should I choose break bulk shipping over container shipping?

Choose break bulk shipping when your cargo is too large, too heavy, or oddly shaped for standard containers—such as turbines, machinery, steel beams, or project cargo. It’s also ideal when shipments need custom handling or routing.

3. Is break bulk shipping more expensive than container shipping?

Not always. While break bulk can involve higher handling costs, it’s often more cost-effective for large or irregular cargo that would otherwise require multiple containers or special modifications.

4. What types of goods are best suited for container shipping?

Container shipping works best for standardized goods like pallets, boxes, electronics, textiles, packaged foods, or small machinery that fit neatly into a 20ft or 40ft container.

- Are there specific ports for break bulk cargo?

Yes. Break bulk shipments use specialized ports with cranes and heavy-lift equipment for oversized cargo.

In the U.S., major break bulk ports include: Port of Houston (TX), Port of New Orleans (LA), Port of Baltimore (MD), Port of Mobile (AL), Port of Charleston (SC), and Port of Philadelphia (PA).

These ports are well-equipped for handling large machinery, steel, and project cargo efficiently.